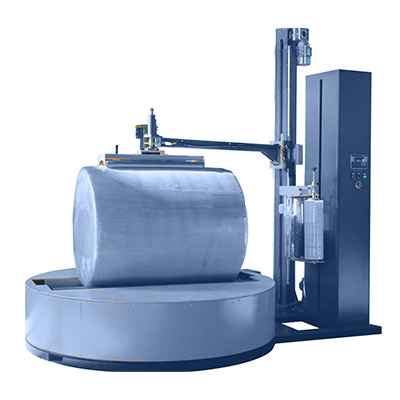

Big Paper Roll Film Packing Machine

| Working Product Diameter | Width : 250 MM To 625 MM Diameter : 350 MM To 850 mm Reel weight : 12 To 150 KG |

|---|---|

| Diameter of Roll (Stretch Film) | Core ID : 75 MM OD: UP TO 200 MM Width :250 MM TO 300 MM |

| Packing Efficiency | 15-35 rolls/hour (Depend On Product ) |

| Turntable Speed | 0 To 20 RPM (Depend On Product) |

| Dia. of Turntable | 1650 mm (As Per Customer Requirement) |

| Roller Specification | Rollers : 2 nos.(m.s) Roller : M.S roller with rubber belt dia. of roller : 205mm roller center distance : 300 mm |

| Motors | Roller Motor : 1 HP Tune Table Motor : 2 HP Power Pre-Stretch Motor: 0.25 HP (2 Nos) Up Down System Motor : 0.5 HP |

| Motor Worm Gear Box | Roller Motor : 1 HP Gear Box Tune Table Motor : 2 HP Gear Box Power Pre-Stretch Motor: 0.25 HP Gear Box (2 Nos) Up Down System Motor : 0.5 HP Gear Box |

| Motor Drive (V.F.D) | Roller Motor : 1 HP Tune Table Motor : 2 HP Power Pre-Stretch Motor: 0.25 HP (2 Nos) |

| UP-Down System | Chain Base Up-Down System With Motor And Linear Shaft |

| Pre-Stretch System | Rubber Mounted Roller Base Automatic Cancer Base Power Pre-Stretch System |

| Ejector System | Up To your Kg [If You Required ] Pneumatic Air Cylinder Base Ejector System |

| Machine Weigth | Approx. 2000kg |

| Features | Advantages |

|---|---|

| • Roll Ejector Up-To Your Kg By Pneumatic Air Cylinders • Automatic Roll Ejector System. • Automatic Holding Of Film. • At Starting Point & Ending Point – Wrap Can Be Adjusted By From Control Panel. |

• Protection Against Moister And Dust • Prevent Telescoping of Rolls • Save Packaging Cost, labour and Time • Better Identification of Warped Product • Gives Stability to Product • Economical Way of Packing • Save from Atmosphere, Rain Etc • Film Save Up To 300 % |